Wire Wrap Screens

Wire Wrap Screens

- 1.Slot size (mm):0.10,0.15,0.2,0.25,0.30-3

- 2.Material:Carbon ,Galvanized steel (LCG),steel treated with plastic spraying,Stainless Steel( 304,316,316L etc.)

- 3.Diameter ranging from 25 mm to800 mm

- 4.End Connection :Plain beveled ends for butt welding or threaded

- Product description: J55/K55/N80/L80/P110/BTC/LTC/STC/Premium Threading/Oil casing,Water Well Casing Pipe,Steel Casing pipe,Tubing,Slotted Liners,Precision Punched Screen,Screen Pipe from Hebei Sloate,Qingxian,China,AL

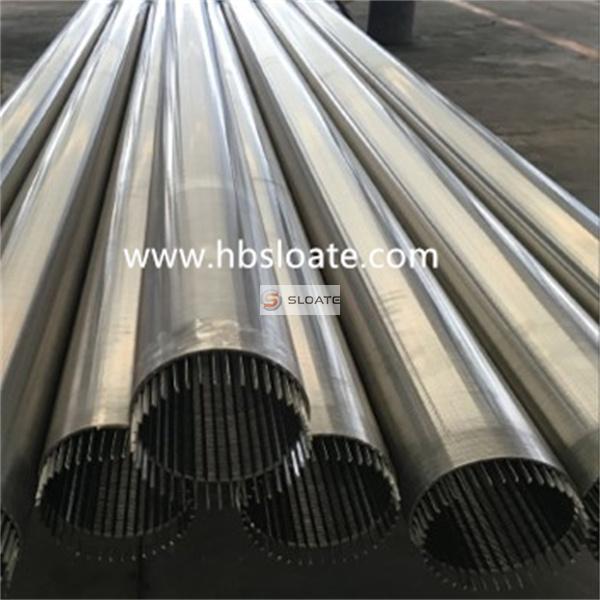

The continuous-slot well screen is widely used throughout the world for water, oil, and gas wells, and is the dominant screen type used in the water well industry. Sloate Continuous-Slot Well Screen is made by winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights. Slot opening for continuous-slot screens are manufactured by spacing successive turns of the outer wire to produce the desired slot size. All slots should be clean and free of burrs and cuttings.Each slot opening between adjacent wires is V-shaped, from the special shape of wire used to form the screen surface. The V-shaped openings designed to be non clogging, are narrowest at the outer face and widen inwardly;

Features:

1. Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2. Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

3. Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

4. Low operational costs: Large open area with an effective flow, high yield and a low pressure drop (dP)

5. Long live: Welded at each intersection creating a strong and durable screen.

6. Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components.

7. Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.Each slot opening between adjacent wires is V-shaped, resulting from the special shape of the wire used to form the screen surface. The V-shaped openings, designed to be non clogging, are narrowest at the outer face and widen inwardly.Continuous-slot screens provide more intake area per unit area of screen surface than any other type. For any given slot size, this type of screen has maximum open area.

|

Screen Size |

Inside Diameter |

Outside Diameter |

OD of Female Threaded End |

||||

|

in |

mm |

In |

mm |

in |

mm |

In |

mm |

|

2 |

51 |

2 |

51 |

25/8 |

67 |

23/4 |

70 |

|

3 |

76 |

3 |

76 |

35/8 |

92 |

33/4 |

95 |

|

4 |

102 |

4 |

102 |

45/8 |

117 |

43/4 |

121 |

|

5 |

127 |

5 |

127 |

55/8 |

143 |

53/4 |

146 |

|

6 |

152 |

6 |

152 |

65/8 |

168 |

7 |

178 |

|

8 |

203 |

8 |

203 |

85/8 |

219 |

91/4 |

235 |

|

10 |

254 |

10 |

254 |

103/4 |

273 |

113/8 |

289 |

|

12 |

305 |

12 |

305 |

123/4 |

324 |

133/8 |

340 |

|

14 |

356 |

131/8 |

333 |

14 |

356 |

— |

— |

|

16 |

406 |

15 |

381 |

16 |

406 |

— |

— |

|

20 |

508 |

18 3/4 |

476 |

20 |

508 |

— |

— |

Latest News

Contact Us

Contact: Liu

Phone: +86 18103379998

Tel: +86-317-3066898

Add: Qingxian,Hebei Province, China

casingpipe

casingpipe casingpipe

casingpipe